|

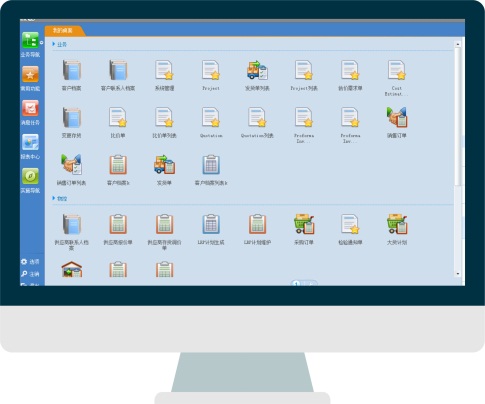

We fully understand, to protect our own business, we have to protect our customer intellectural properties and privacies. so we have deployed a very strict secrecy measurement for customers’ confidential information, which include but limited to:

any and all information, sales and business information, customer information, technical data, or knowhow, including but not limited to, information relating to research, products, product designs and materials, formulas, software, services, development, inventions, processes and methods, specifications, engineering information, marketing information, pricing, costs, internal procedures, business and marketing plans or strategies, finances, and business opportunities, disclosed by the customer to Kenvox either directly or indirectly, in writing, machine readable or other tangible form, orally or visually. Confidential Information also includes:

(a) information and materials that are identified in writing as “Confidential” at the time of disclosure, or

(b) information disclosed orally or in some other non-written form and/or subsequently identified in writing as “Confidential” within a reasonable time period following the initial disclosure of such information. |